Structure¶

The afem.structure package provides the low-level types and tools that the

user can leverage to build more complete and useful aircraft structural models.

This package is the main focus of the entire AFEM project and is built on top

of almost all the other packages. The entities and tools can be imported by:

from afem.structure import *

The sub-sections and example below will describe the package in more detail, but some discussion about the general modeling approach and “best-practices” is helpful. The AFEM library does not necessarily provide new methods for building structural geometry, but rather focuses on providing a more specialized API and workflow that streamlines and automates many of the repetitive and mundane tasks typically encountered in the traditional modeling process. The end result is still B-Rep topology and a finite element model and therefore is still subject to the limitations and/or weaknesses of these modeling paradigms. This may include robustness of Boolean operations within the geometric modeling kernel or the quality of the finite element mesh. Through experience, a procedure has been found to work well for a wide range of applications:

- Build initial parts

The first step of the process is simply defining the initial reference geometry and shape for the part without any real topological connection to any others. At this point, the parts and their shapes can be used to build others but there is less concern or emphasis for details like establishing topologically congruent edges. The goal for this initial step is to define the initial part shape as quickly and easily as possible while keeping its representation flexible.

- Join parts

The initial part shapes may be connected spatially but disconnected topologically. It’s during this step that modeling tools are used to join the various shapes together to form shared and congruent edges between the connecting parts. Modeling flexibility is reduced after this step and joining operations are best done to large groups of connected parts so that joints with multiple and complex intersections can be handled robustly. If new parts are created after this step and joined locally with ones that already exist and have been joined, it is not guaranteed that the overall model will maintain the proper topology. In this case, it would be better to define the part in the first step and include in the overall joining operation. The structure usually involved in this step is the internal structure such as ribs, spars, bulkheads, frames, etc. The external skin is usually joined in a later step.

- Trim parts

After the parts have been joined, it is usually the case that certain pieces or regions of the parts should be discarded. For example, if modeling only the primary load-carrying structure of a wing box, the regions of the ribs aft of the rear spar may need to be removed from the model. In an interactive GUI, this would be a “select and delete” action. Typically, no new topology is introduced in this step but rather certain regions of the existing model are removed without modifying others. For the wing box example mentioned earlier, this may be first identifying the faces aft of the rear spar using various tools and then removing those faces from the shape. As mentioned earlier, Step 2 usually involves joining internal structure and not necessarily external structure like the wing skin. Joining the external skins with internal structure is is best done after the internal structure has been joined and trimmed. This avoids creating unnecessary edges in the shape of the external structure since internal regions will be discarded.

- Applying meshing controls

At this point, it is assumed the geometrical modeling operations are complete and now a finite element mesh can be created. Various tools are provided for applying both global and local meshing controls on any part, shape, or sub-shape. The number of elements along an edge or max element size on a face can be applied on a per edge or face level.

- Generate FEM

The last step is simply computing the FEM considering the global shape to mesh and all the local meshing controls (if any). The result is a mesh data structure that can be supplied to downstream processes. Local mesh data for a part, shape, or sub-shape can be extracted from this global mesh to further support downstream tools and processes.

The basic wing box example below goes through each of these steps in more detail and highlights the key features, types, and tools in the AFEM toolkit:

from afem.config import Settings

from afem.exchange import ImportVSP

from afem.geometry import *

from afem.graphics import Viewer

from afem.structure import *

from afem.topology import *

Settings.log_to_console()

# Set units to inch.

Settings.set_units('in')

# Initialize a viewer

gui = Viewer()

# Import an OpenVSP model that includes OML reference geometry

fn = r'../models/simple_wing.stp'

vsp_import = ImportVSP(fn)

wing = vsp_import['WingGeom']

wing.set_color(1., 0., 0.)

wing.set_transparency(0.75)

gui.add(wing.sref, wing)

gui.start()

gui.clear()

# Define a group to put the structure in

wingbox = GroupAPI.create_group('wing box')

spars_assy = wingbox.create_subgroup('spar assy', active=True)

ribs_assy = wingbox.create_subgroup('rib assy', active=False)

# Define a front spar between parameters on the wing reference surface

fspar = SparByParameters('fspar', 0.15, 0.1, 0.15, 0.98, wing).part

gui.add(wing.sref, fspar, fspar.cref, fspar.cref.p1, fspar.cref.p2)

gui.start()

# Define a rear spar between parameters on the wing reference surface

rspar = SparByParameters('rspar', 0.65, 0.1, 0.65, 0.98, wing).part

gui.add(rspar, rspar.cref, rspar.cref.p1, rspar.cref.p2)

gui.start()

# Activate rib assembly

ribs_assy.activate()

# Define root rib between front and rear spar

root = RibByPoints('root', fspar.cref.p1, rspar.cref.p1, wing).part

gui.add(root, root.cref, root.cref.p1, root.cref.p2)

gui.start()

# Define tip rib between front and rear spar

tip = RibByPoints('tip', fspar.cref.p2, rspar.cref.p2, wing).part

gui.add(tip, tip.cref, tip.cref.p1, tip.cref.p2)

gui.start()

# Add ribs between root and tip perpendicular to rear spar reference curve

ribs = RibsAlongCurveByDistance('rib', rspar.cref, 30., fspar, rspar, wing,

d1=30., d2=-30.).parts

for rib in ribs:

gui.add(rib, rib.cref, rib.cref.p1, rib.cref.p2)

gui.start()

# Activate spar assembly

spars_assy.activate()

# Add a front center spar considering the intersection between the front

# spar and the root rib. If this is not considered, the front center spar

# may be oriented in such a way that causes it to have a gap with the front

# spar and root rib.

p1 = wing.sref.eval(0.25, .0)

pln = PlaneByIntersectingShapes(fspar.shape, root.shape, p1).plane

fcspar = SparByPoints('fcspar', p1, root.cref.p1, wing, pln).part

gui.add(fcspar, fcspar.cref, fcspar.cref.p1, fcspar.cref.p2)

gui.start()

# Add rear center spar

p1 = wing.sref.eval(0.75, .0)

pln = PlaneByIntersectingShapes(rspar.shape, root.shape, p1).plane

rcspar = SparByPoints('rcspar', p1, root.cref.p2, wing, pln).part

gui.add(rcspar, rcspar.cref, rcspar.cref.p1, rcspar.cref.p2)

gui.start()

# Activate rib assembly

ribs_assy.activate()

# Add center ribs using a reference plane alonge the rear center spar

ref_pln = PlaneByAxes(origin=(0., 0., 0.), axes='xz').plane

ribs = RibsAlongCurveByNumber('center rib', rcspar.cref, 3, fcspar, rcspar,

wing, ref_pln, d1=6, d2=-18).parts

for rib in ribs:

gui.add(rib, rib.cref, rib.cref.p1, rib.cref.p2)

gui.start()

# Draw the part reference curves to see what the layout will eventually

# look like

gui.clear()

gui.add(wing.sref)

for part in wingbox.get_parts():

gui.add(part.cref)

gui.start()

# Join the internal structure using their reference curves to check for

# actual intersection

internal_parts = wingbox.get_parts()

FuseSurfacePartsByCref(internal_parts)

gui.add(wingbox)

gui.start()

# Discard faces of parts using the reference curve

DiscardByCref(internal_parts)

gui.clear()

gui.add(wingbox)

gui.start()

# Activate wingbox assembly

wingbox.activate()

# Extract the shell of wing to define the wing skin

skin = SkinByBody('skin', wing).part

skin.set_transparency(0.5)

gui.add(skin)

gui.start()

# Join the wing skin with the internal structure

skin.fuse(*internal_parts)

# Discard wing skin that is touching the wing reference surface. This

# should leave only the upper and lower skins.

print(skin.shape.shape_type)

skin.discard_by_dmin(wing.sref, 1.)

# After removing the faces, the skin is now a compound of two shells, one

# upper shell and one lower. Use the Part.fix() to alter the shape from an

# invalid shell to a compound of two shells.

print('Skin shape type before fix:', skin.shape.shape_type)

skin.fix()

print('Skin shape type after fix:', skin.shape.shape_type)

gui.clear()

gui.add(wingbox)

gui.start()

# Check for free edges

shape = GroupAPI.get_shape()

tool = ExploreFreeEdges(shape)

gui.clear()

gui.add(shape, *tool.free_edges)

gui.start()

# Begin meshing

print('Creating mesh...')

mesh = MeshVehicle(4.)

# Set number of elements between spars and skin edges

spars = wingbox.get_parts(rtype=Spar)

skins = wingbox.get_parts(rtype=Skin)

shape = ExploreParts.shared_edges(spars, skins, True)

mesh.set_max_length_1d(4., shape)

# Set number of elements between spar and rib edges

ribs = wingbox.get_parts(rtype=Rib)

shape = ExploreParts.shared_edges(spars, ribs, True)

mesh.set_number_segments_1d(4, shape)

# Apply structured quadrilateral mesh

shape = ExploreParts.shared_edges(skins, ribs, True)

mesh.set_number_segments_1d(15, shape)

for part in wingbox.get_parts():

mesh.set_quadrangle_2d(part.shape)

# Compute the mesh

mesh.compute()

# View

gui.clear()

gui.add(mesh)

gui.start()

# Create node groups of the spars and ribs

spar_nodes = mesh.create_node_group(spars_assy.get_shape())

rib_nodes = mesh.create_node_group(ribs_assy.get_shape())

gui.clear()

gui.add(spar_nodes, rib_nodes)

gui.start()

# Find common nodes between spars and ribs

shared_nodes = spar_nodes.intersect(rib_nodes, 'spar and rib nodes')

gui.clear()

gui.add(mesh, shared_nodes)

gui.start()

# Create edge groups of front spar and skin and find shared edges

fspar_edges = mesh.create_edge_group(fspar.shape)

skin_edges = mesh.create_edge_group(skin.shape)

shared_edges = skin_edges.intersect(fspar_edges)

gui.clear()

gui.add(shared_edges)

gui.start()

# Export mesh to Nastran

mesh.export_nastran('structure_basic.bdf')

The procedure starts by settings the default length units to inches:

Settings.set_units('in')

This is done before importing the STEP file so that it can be properly translated upon import. In this example a simple wing geometry generated by OpenVSP will be used:

fn = r'../models/simple_wing.stp'

vsp_import = ImportVSP(fn)

wing = vsp_import['WingGeom']

wing.set_color(1., 0., 0.)

wing.set_transparency(0.75)

Note that this model was generated with a specialized build of OpenVSP that

includes additional reference geometry in the STEP export tool. For more

details see the section on OpenVSP import. Upon import, a

Body type will be created that contains the solid that represents the

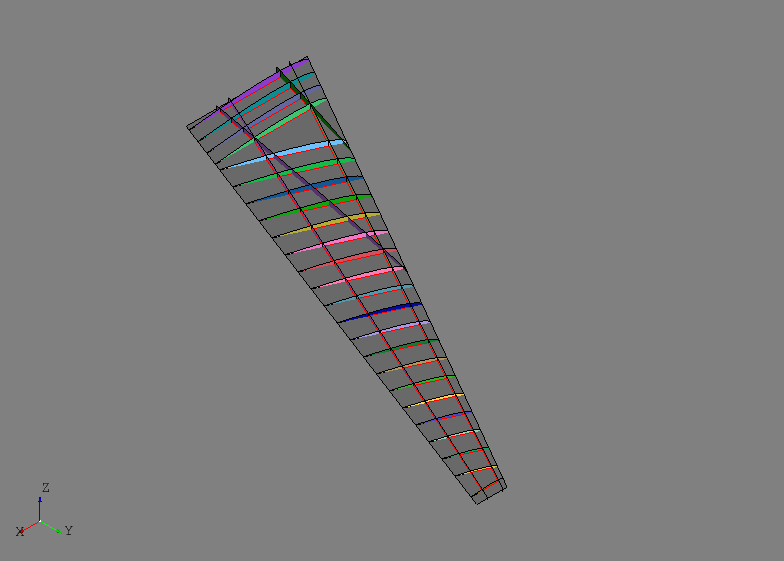

wing as well as the wing reference surface as shown below.

The reference surface of the wing in this case is lofted through the chord lines of each wing section and provides the basis for the parametric (i.e, uv) definition of the wing. For this particular model, the u-direction will correspond to chord and v-direction will correspond to span. The leading edge will be at u=0 and the trailing edge at u=1, while the root is at v=0 and the tip at v=1. This is not an absolute rule and is completely dependent on the underlying surface set as the wing’s reference surface. This flexibility was left open in case different users found other parametrization techniques more intuitive or suitable for a given application.

To provide model organization, three different Group entities are

created using the GroupAPI tool:

wingbox = GroupAPI.create_group('wing box')

spars_assy = wingbox.create_subgroup('spar assy', active=True)

ribs_assy = wingbox.create_subgroup('rib assy', active=False)

The wingbox will be the top-level group and sub-groups for the spars

and ribs are created as shown. Note that the spar assembly was set

active=True while the rib assembly was False. When a Part is

created it is by default placed in the active Group if one was

not provided. Since spars are the first items created in this example, the

spar assembly was made active. The Group can also be supplied to the

Part builder tool directly.

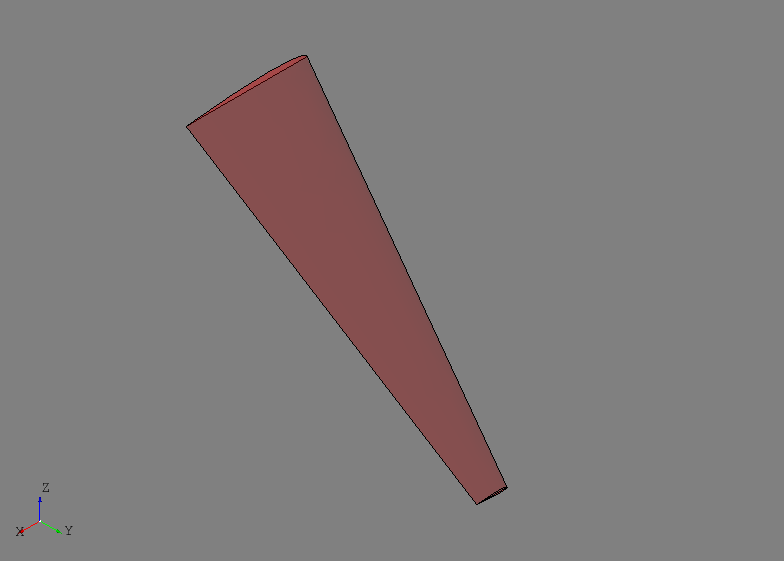

A front spar is defined in the parametric domain of the wing using its

reference surface and the SparByParameters tool:

fspar = SparByParameters('fspar', 0.15, 0.1, 0.15, 0.98, wing).part

Note that the uv parameters are relative to the reference surface of the

Body supplied to this tool. This tool, and others like it, are

designed to operate as described in Step 1 above and generate the initial

shape of the part. The initial shape is formed by simply finding the

intersecting material between the Body solid and a basis shape. The

SparByParameters tool, and others like it, can usually be initialized

with an optional basis_shape input. If provided, this basis shape will be

used to find the initial part shape and has few limitations (i.e., could be

curvilinear). If a basis shape is not provided, for this tool a plane is

automatically defined between two points on the wing reference surface defined

by the uv parameters and a third which is offset in the normal direction at

the (u1, v1) location. This approach usually results in a reasonable

orientation of a planar part in case the wing is twists or changes dihedral.

This is another reason why is it usually good practice, if not required, to

provide define and attach a reference surface to the input Body.

At this point the initial shape may extend beyond the anticipated start and end locations since the process has simply found an intersection between the wing solid and a plane. Not trimming the actual shape to its start and end locations is done because: 1) the interfacing parts and shapes are not yet defined and 2) because no assumption is made about the shape of the interfacing structure. Point 2 is particularly important because although assumptions could be made and the shape trimmed with a plane at the start and end points based on the uv parameters for example, it is important to keep it general in case the interfacing structure is actually some curvilinear shape that is not yet defined (e.g., a bulkhead in a fuselage).

Although the part shape is not initially trimmed, having some way of tracking

where it will generally start and stop is a valuable reference. In the case

of the front spar, this is accomplished by building and associating a

Part reference curve within the SparByParameters process.

This reference curve is constructed by intersecting the wing’s reference

surface with the part’s basis shape (a default plane in this case). The

resulting intersection is converted into a TrimmedCurve entity.

Initially this curve also extends the full length of the reference surface, but

the points defined by the uv parameters are used to bound the curve. These

points and the trimmed curve represent a planform view of where the part will

generally start and end on the wing, even though the spar’s shape at this point

still extends the full volume. The initial part shape, its reference curve

(shown in red), and its start and end points (shown in yellow) are shown below.

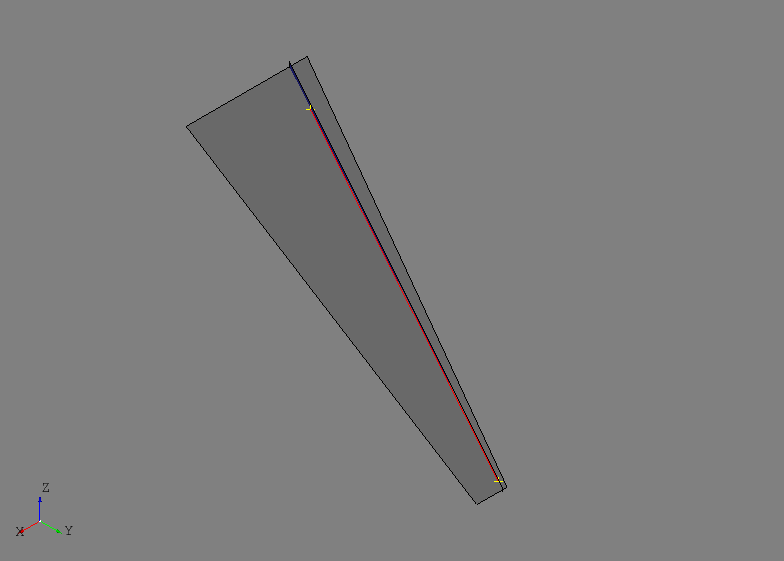

The rear spar is defined using the same tool but at 65% chord:

rspar = SparByParameters('rspar', 0.65, 0.1, 0.65, 0.98, wing).part

The initial shapes of the front and rear spar as well as their reference geometry are shown below.

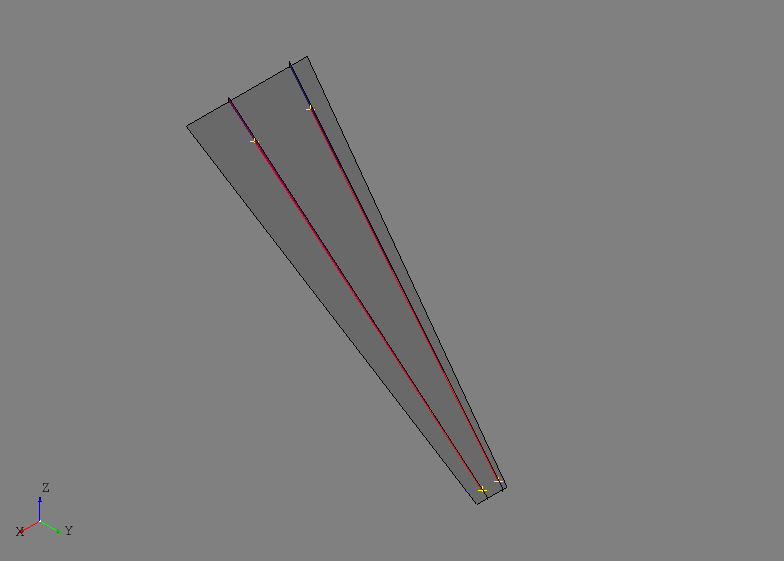

After activating the ribs assembly, ribs will be defined at the root and tip of

the front and rear spars using the RibByPoints tool. In this tool,

start and end points are given instead of parameters on the wing reference

surface. Although, these points should generally lie close to or on the wing’s

reference surface because the tool simply inverts them to find uv parameters

and then uses the RibByParameters tool. The root and tip ribs are

defined as:

root = RibByPoints('root', fspar.cref.p1, rspar.cref.p1, wing).part

tip = RibByPoints('tip', fspar.cref.p2, rspar.cref.p2, wing).part

The root and tip ribs are shown below along with their reference geometry.

Generating multiple intermediate ribs between the root and tip will be

accomplished using the RibsAlongCurveByDistance tool. This tool

uses a curve and a spacing to distribute planes along the curve that become

the basis shapes for the ribs. The parameters shape1 and shape2 define

the start and end points for the rib reference curves and d1 and d2

control initial offset spacing at the first and last points of the curve.

Additionally, a reference plane can be supplied using the ref_pln

parameter which will define the plane orientation at each point along the

curve. If no reference plane is provided, then the first derivative of the

curve will be used to define the normal orientation of the plane.

ribs = RibsAlongCurveByDistance('rib', rspar.cref, 30., fspar, rspar, wing,

d1=30., d2=-30.).parts

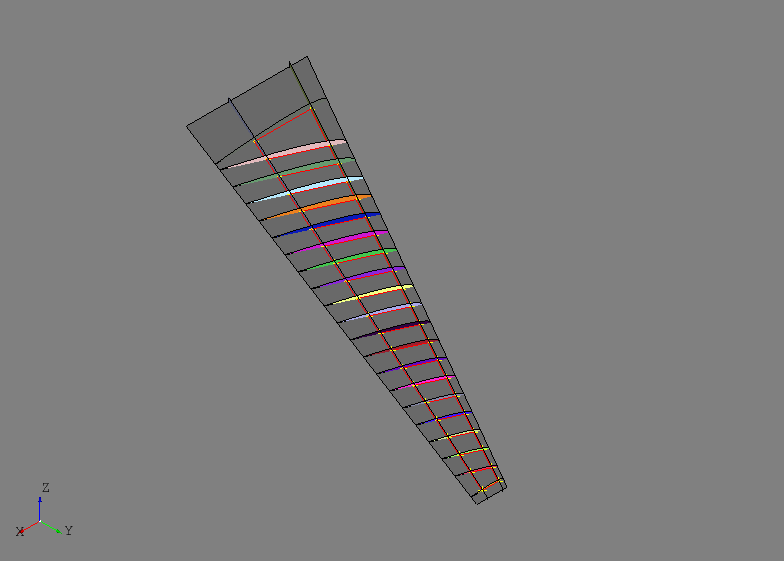

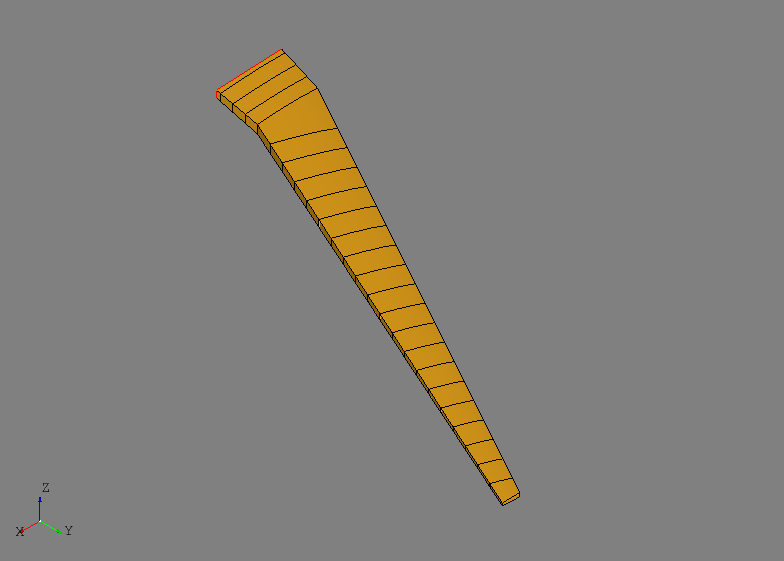

Since the rear spar reference curve was used without providing a reference plane, this tool makes the ribs perpendicular to the rear spar. Remember that all the images to this point show the initial part shapes without any joining or trimming. The images may begin to look cluttered and strange, but it will become clear in later steps how to achieve the desired result.

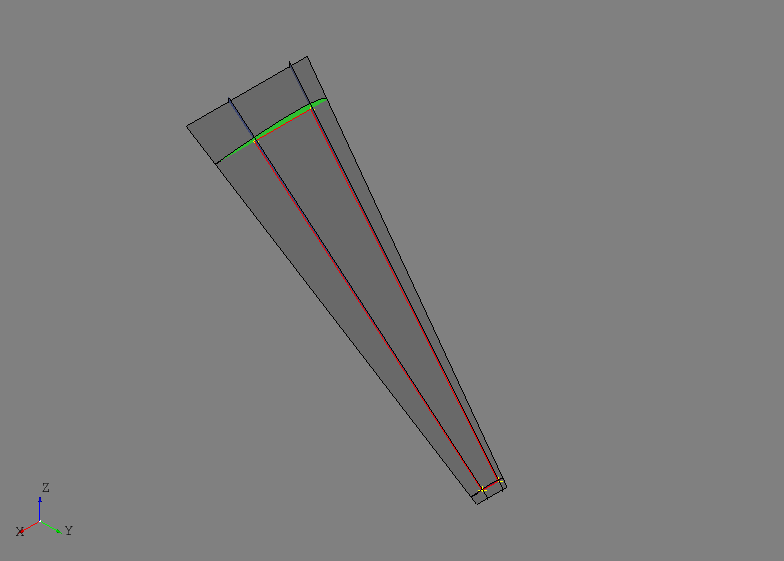

Simple center wing box structure will be modeled that includes a front and rear

center spar as well as some center ribs oriented in the global xz-plane. This

highlights an example where some additional thought and modeling is required

before the automated tools can be used. The end point of the front center

spar will interface with both the front spar and the root rib and therefore

should be oriented such that is intersects cleanly. If the automated tools

are used without providing a basis shape, it is likely the the automated

orientation will not line up properly with the front spar and root rib

intersection. To resolve this, the intersection between the front spar and

root rib will be used to define the basis shape of the front center spar. The

tool PlaneByIntersectingShapes will return a plane based on the

intersection of the two shapes if the edges of the resulting intersection are

planar. To fully define the plane, a third reference point is needed that is

not collinear with the intersection and is usually the other point of the

structure being defined. The same process is done for the rear center spar and

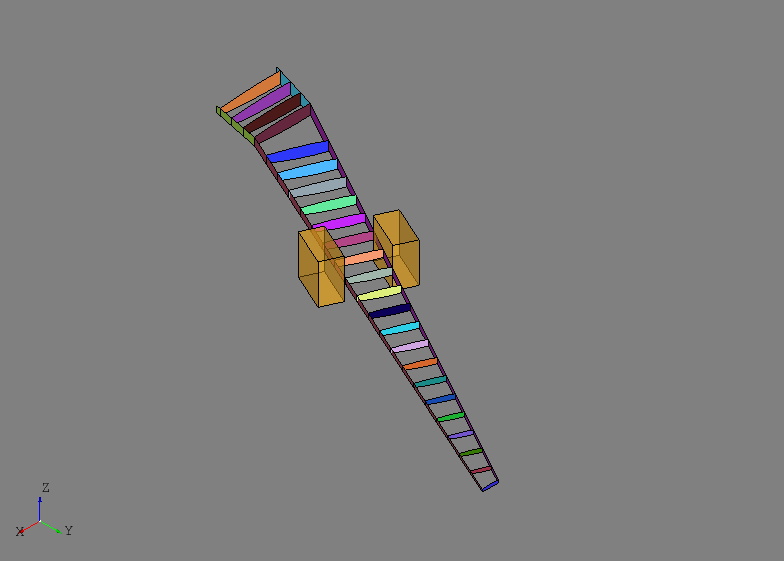

the results are shown below.

# Front center spar

p1 = wing.sref.eval(0.25, .0)

pln = PlaneByIntersectingShapes(fspar.shape, root.shape, p1).plane

fcspar = SparByPoints('fcspar', p1, root.cref.p1, wing, pln).part

# Rear center spar

p1 = wing.sref.eval(0.75, .0)

pln = PlaneByIntersectingShapes(rspar.shape, root.shape, p1).plane

rcspar = SparByPoints('rcspar', p1, root.cref.p2, wing, pln).part

Center wing box ribs are added using the :class`.RibsAlongCurveByNumber` tool and this time a basis shape (the xz-plane) will be supplied.

ref_pln = PlaneByAxes(origin=(0., 0., 0.), axes='xz').plane

ribs = RibsAlongCurveByNumber('center rib', rcspar.cref, 3, fcspar, rcspar,

wing, ref_pln, d1=6, d2=-18).parts

At this point it is helpful to plot only the wing reference surface and the reference curves of each of the parts defined thus far. This will be a helpful representation of how the structure will generally look at the end of the process.

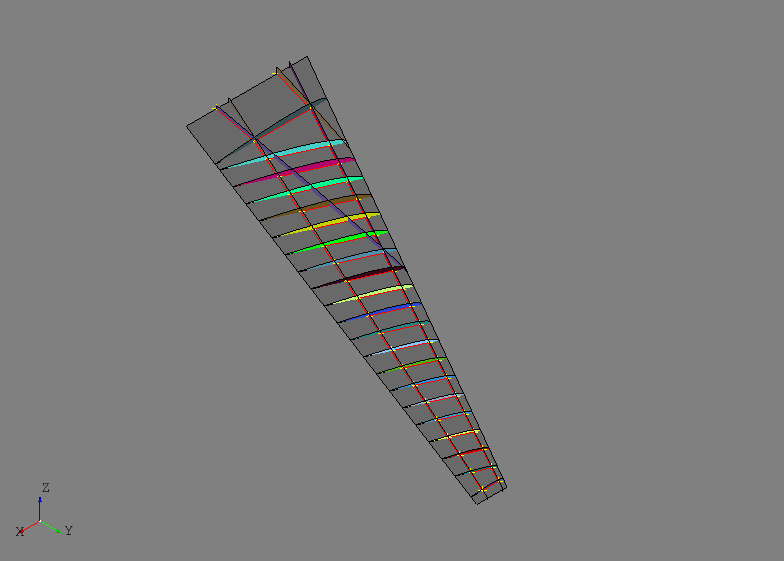

Joining the internal structure can now be done using a specialized

FuseSurfacePartsByCref tool. This tool will take a sequence of

SurfacePart entities and join them only if their reference curves

intersect. With this tool, even though the initial shapes may visually

intersect in undesired regions, the reference curves are used as a way to

intelligently select which parts should actually be topologically joined with

one another.

internal_parts = wingbox.get_parts()

FuseSurfacePartsByCref(internal_parts)

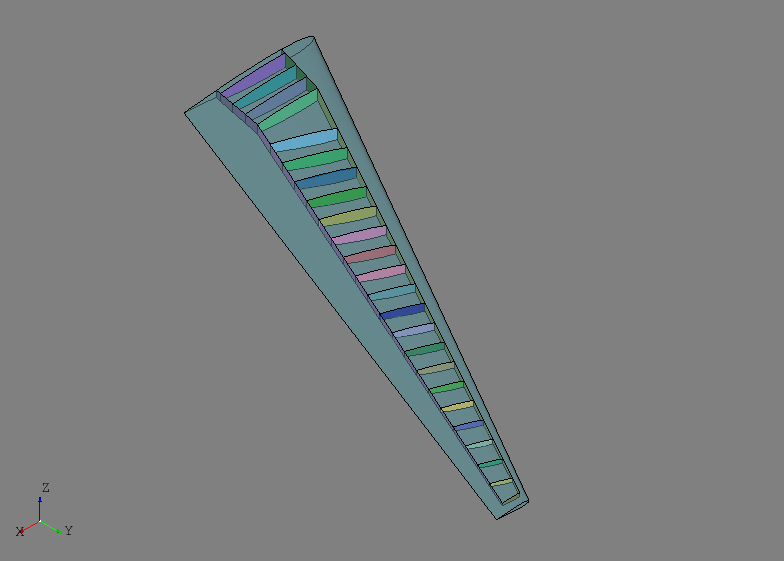

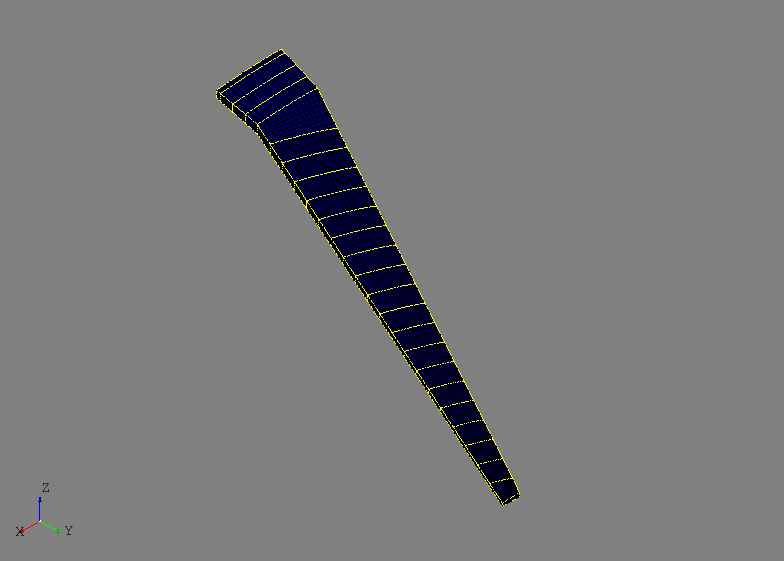

It may not be obvious in the image below, but after the joining operation new edges only exist between the parts that had intersecting reference curves.

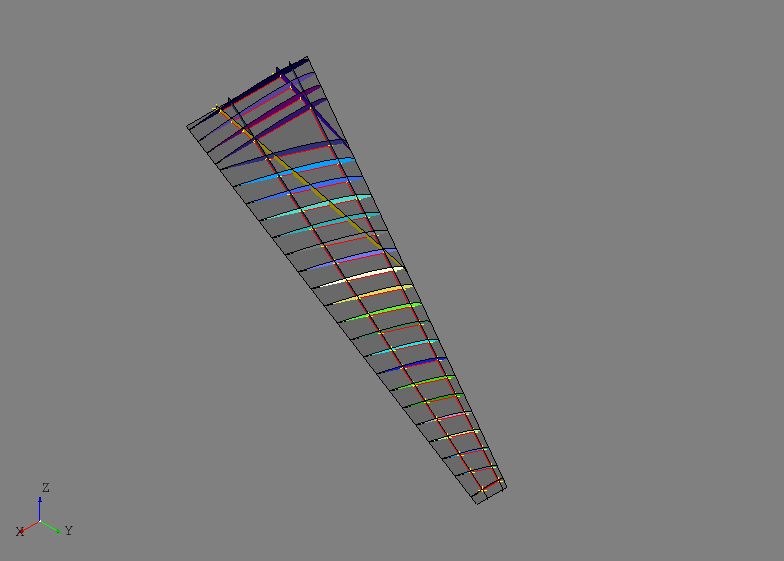

After the joining operation the initial shapes have been updated with new

shapes that are now trimmed with the other parts and should share congruent

edges. Although, there are still some regions of some of the parts that must

be discarded in this example to get the desired result. In an interactive

GUI, this would be accomplished by a simple point-and-click delete operation.

Since AFEM is most likely operating in an automated and scripted

environment, other means of replicating the point-and-click action must be

developed. In this example the DiscardByCref tool is used:

DiscardByCref(internal_parts)

For each part in the input, this will try and determine which sub-shapes should

be discarded (i.e., deleted) based on their relationship to the reference curve

of the part. At each end of the part reference curve, the first derivatives of

the curve are used to define normal directions for two planes located at the

start and end points. These planes and their normal direction attempt to define

the “outside” region of the part. For each relevant sub-shape, which will be

the edges of a CurvePart or faces of a SurfacePart, the

centroid of the shape will be classified as either “inside” or “outside” the

part based on its location relative to the two planes. If the centroid is

classified as outside then the sub-shape is removed and the part shape is

updated. This method and tool are based on some assumptions about the general

part shape and it having a reference curve. There are other discarding tools

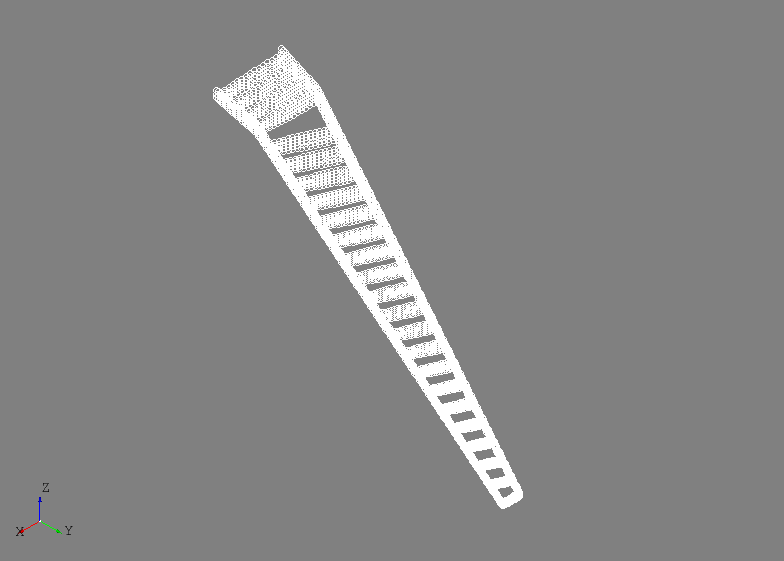

available for general or complex cases. The result after discarding faces of

the internal structure based on their reference curves is shown below along

with one of the “outside” regions for one of the ribs. Note that the regions

are drawn as finite boxes, but they are actually infinite boxes in the

direction away from the part reference curve.

After the internal structure is defined and joined, the next step is usually

initializing any external skins and joining them with the internal structure.

The SkinByBody extract the outer shell from a solid and uses that

as the shape for a Skin entity:

skin = SkinByBody('skin', wing).part

The skin.fuse(other_parts) will join the input parts with the skin but it does not check or join the input parts with one another. This is the desired behavior since they have already been joined:

skin.fuse(*internal_parts)

Joining the external skin with all the internal structure at once improves the chances of obtaining congruent edges between all the interfacing structure. It is generally recommended that joining of external skins to internal structure is saved for later in the geometric modeling process. The skin and internal structure are shown below.

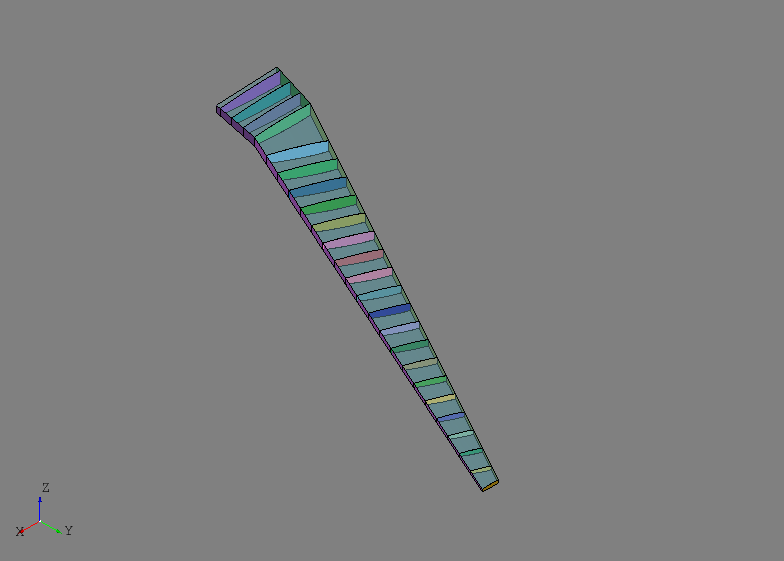

For this example, the wing skin regions outside the primary load-carrying area of the wing box are to be excluded:

skin.discard_by_dmin(wing.sref, 1.)

This method will check each sub-shape of the part for its distance to some reference entity, in this case the wing reference surface. If the distance is below some threshold then the sub-shape is discarded from the part. For this model, any skin region that touches the wing reference surface is either along the leading or trailing edge and outside the primary load-carrying area. The resulting wing box is shown below.

In the example, the skin.fix() method is used to check the shape of the

skin. This method is a general shape checking and fixing tool that can catch

and repair errors that may arise during the modeling process. In this case,

the skin was originally a single Shell, but after joining and

discarding become two disconnected shapes, one upper and one lower. To remedy

this, the skin.fix() repaired the shape by changing its type to a

:class`.Compound` made up of two Shell entities.

At this point the geometric modeling process is complete and the following

code will check the shape for any free edges which may indicate an error. The

shape variable below is a single top-level shape put together from all of

the parts.

shape = GroupAPI.get_shape()

tool = ExploreFreeEdges(shape)

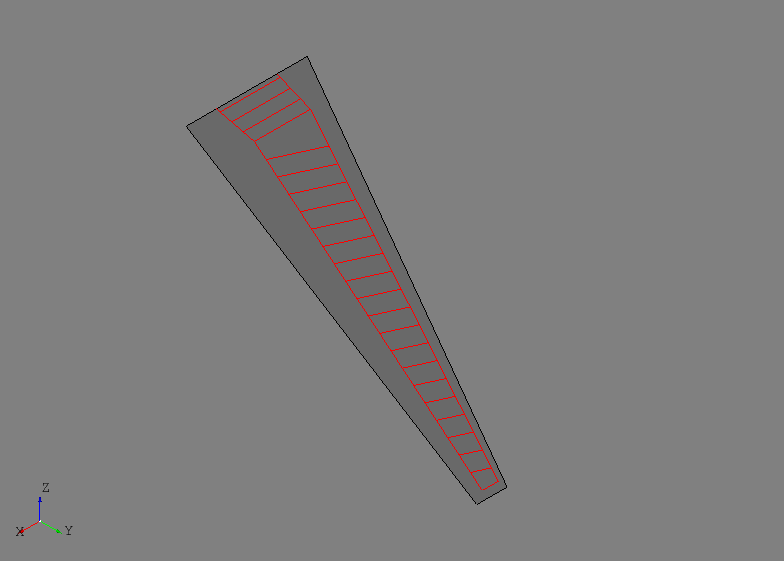

The free edges of tool are shown below with the checked geometry. Note that

the only free edges (shown in red) found were along the root of the model which

is expected since now structure was modeled there.

The next step is the process is usually the generation of Finite Element Model

(FEM) data. For this task, AFEM focuses on providing the needed level of

access to the various shapes of the model to conveniently apply meshing

controls. Rules and best practices for airframe meshing are typically dependent

on the application (e.g., loads vs. deflection model) and/or the user’s own

experience and heuristics. Developing fully-automated, widely applicable, and

robust rules for meshing was deemed impractical and outside the scope of this

project. Instead, effort was directed towards developing streamlined tools to

enable the user to efficiently define their own controls. The low-level

meshing controls are best described in the afem.smesh documentation.

For this example, the MeshVehicle tool provides a convenient API to

define and apply both global and local meshing controls to the desired regions.

The MeshVehicle tool is not a one-size-fits all tool, but is more

an example of a meshing utility that could be developed for more advanced use

cases. Although, it does provide a wide range of functionality all in one

place:

mesh = MeshVehicle(4.)

Upon initialization, this tool will define a top-level global shape derived

from the master group from the GroupAPI tool. The target_size

parameter is used to define a global quad-dominated meshing algorithm that will

be applied to the entire shape absent of any other local mesh controls.

This simple example is actually suited for more of a structured meshing

approach with the right local edge meshing controls. The code below gathers

parts of specific types together and then the ExploreParts tool is

used to retrieve a Compound that contains only the shared edges.

Here, the edges shared by both the spars and skin will have a maximum edge

length of four.

spars = wingbox.get_parts(rtype=Spar)

skins = wingbox.get_parts(rtype=Skin)

shape = ExploreParts.shared_edges(spars, skins, True)

mesh.set_max_length_1d(4., shape)

In similar fashion, the shared edges between the ribs and spars will have four elements along their length.

ribs = wingbox.get_parts(rtype=Rib)

shape = ExploreParts.shared_edges(spars, ribs, True)

mesh.set_number_segments_1d(4, shape)

Next, the edges shared between the ribs and the skin will have fifteen elements along their length.

shape = ExploreParts.shared_edges(skins, ribs, True)

mesh.set_number_segments_1d(15, shape)

Since these controls provide a fairly structured 1-D meshing pattern, a structured quadrilateral algorithm will be applied to all the applicable faces of the model.

for part in wingbox.get_parts():

mesh.set_quadrangle_2d(part.shape)

Finally, the mesh can be computed:

mesh.compute()

The nearly all structured quadrilateral mesh is shown below.

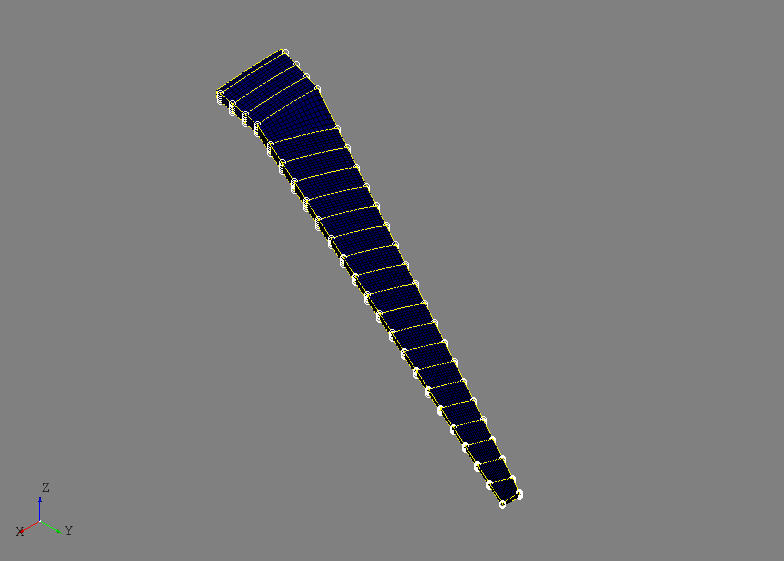

A convenient way to work with the mesh data is to create mesh groups for different mesh types (e.g., node, edge, or face). Mesh groups can be created before the mesh is computed and are derived and associated to a shape. Node groups for the spars and ribs can be defined by:

spar_nodes = mesh.create_node_group(spars_assy.get_shape())

rib_nodes = mesh.create_node_group(ribs_assy.get_shape())

The nodes in these groups are shown below.

Useful information can be derived from these mesh groups like the shared nodes between two different groups. In this example, the shared nodes between the spars and ribs can be obtained by an intersection algorithm:

shared_nodes = spar_nodes.intersect(rib_nodes, 'spar and rib nodes')

The shared nodes are shown below. The same could be done for mesh edge groups created from the same parts.

Mesh edge groups can created from the front spar and the wing skin and shared edges are calculated by:

fspar_edges = mesh.create_edge_group(fspar.shape)

skin_edges = mesh.create_edge_group(skin.shape)

shared_edges = skin_edges.intersect(fspar_edges)

This could be one way of extract spar cap elements from the mesh and assigning FEM properties in downstream properties. The shared mesh edges are shown below.

As a last example, the experimental Nastran export tool can be accessed from

the MeshVehicle tool to output the entire mesh to a Nastran bulk

data file:

mesh.export_nastran('structure_basic.bdf')

To date, no materials or element properties are include in AFEM so this file only contains the nodes and elements. Although, this could be part of future development.